19) BATUR3D Painting Process Development Story

Hello everyone. Here is a new application developed by BATUR3D.

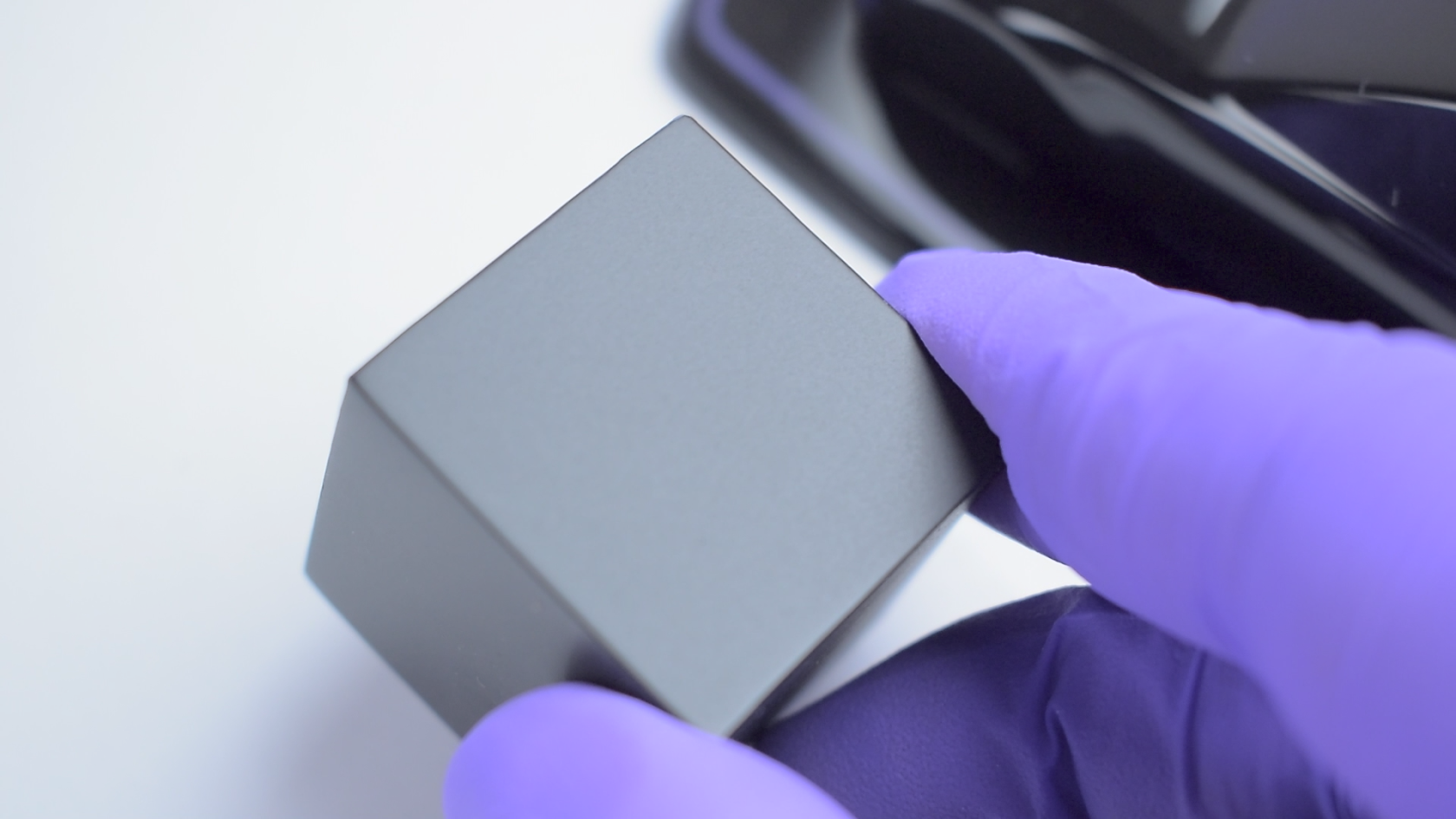

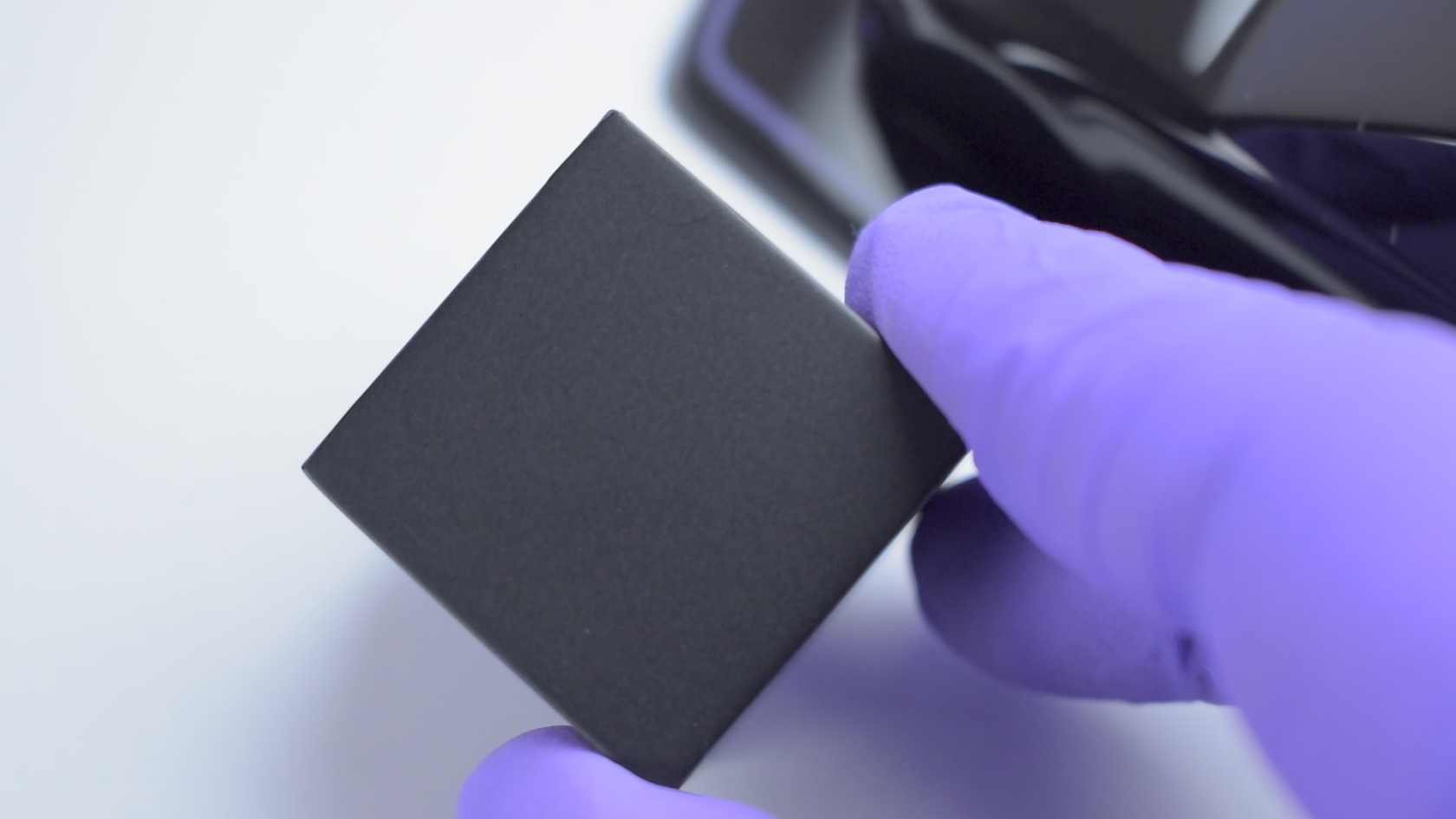

Working with 3 Step, BATUR3D PAINTING™ is now ready to use. Optimized for premium quality. A minimal and practical application opportunity emerged. With BATUR3D POLISHING™, we can achieve flawless and flat surfaces. We can get polished prints in the color of the filament we use. The color possibilities in the polishing system are limited only to the color scale of the filament. Thanks to BATUR3D PAINTING™, we now have the opportunity to work in a very wide color scale. Matte Black surface finish is also possible now. The use of matte black can be very beneficial, especially in parts that are in constant contact. In hand contact, matte black can remain intact for a long time compared to shiny parts. An example of an application can be seen in the pictures.

Many parameters were optimized when installing the polishing system. So the best working options have been discovered. For example, sandpaper selections are very close to the best according to material characteristics and working style. In this way, it can be applied to alternative systems when successful choices are made with precision. Thus, the painting system emerged with the same theoretical foundation. Surface treatments consist of step stops. A micron level dance choreography. From the initial surface roughness to the finish surface roughness is reached by passing through these stops. These stops can also be common to many transactions.

Those who have examined the paint of their car have noticed. A close look at the paint of the car appears to be slightly wavy. After dyeing, an image called orange peel appears. Polishing, on the other hand, provides an artistic and flawless output. Our first choice in visual presentation is the polishing system. Polishing can be preferred for design prototyping. It provides a better understanding of the surfaces as there is no fluctuation. If the polished parts are to be contacted continuously, protection can be provided by nano ceramic coating. Our choice is the painting system for its practicality and wide color scale. For example, if a car mirror cover will be produced with 3D printing, the painting system may be preferred. In this way, a special color for the paint code of the car can be applied to the mirror cover. If the user interface such as the joystick is a piece, painting and matte black paint can be preferred. The resulting piece can be used for a long time without deformation. In this way, we can get Premium 3D Prints with polished and painted outputs through two different applications.

No comments to display

No comments to display